Laser welding michinainzira inoshanda uye chaiyo yewelding inoshandisa yakakwirira-simba-density laser danda semhepo inopisa.Laser welding ndechimwe chezvinhu zvakakosha zvekushandiswa kwelaser material processing technology.Mumakore ekuma1970, yainyanya kushandiswa kugadzira zvinhu zvakatetepa-nemadziro uye yakaderera-kumhanya welding.Iyo welding process ndeye thermal conduction type, ndiko kuti, pamusoro peiyo workpiece inopisa nelaser mwaranzi, uye kupisa kwepamusoro kunopararira kune mukati kuburikidza nekupisa kwekushisa.Nekudzora hupamhi, simba, simba repamusoro uye kudzokorora frequency ye laser pulse uye mamwe ma paramita kunyungudutsa workpiece uye kugadzira chaiyo yakanyungudutswa dziva.Nekuda kwemabhenefiti ayo akasiyana, yakave yakabudirira kushandiswa mukukwenenzvera welding yezvidiki uye zvidiki zvikamu.

一、Welding maitiro

Iyo ndeye fusion welding, iyo inoshandisa laser beam sesimba sosi yekukanganisa pajoinhi reweldment.

Iyo laser beam inogona kutungamirwa neye flat optical element, senge girazi, uye yozoratidzwa pamusono we weld nechinhu chinotarisa chinotarisa kana girazi.

Laser welding is non-contact welding, hapana kumanikidzwa kunodiwa panguva yekushanda, asi inert gasi inodiwa kudzivirira oxidation yedziva rakanyungudutswa, uye simbi yekuzadza inomboshandiswa nguva nenguva.

Laser welding inogona kusanganiswa neMIG welding kuti igadzire laser MIG composite welding kuti iwane yakakura yekupinda welding, uye kupisa kwekuisa kunoderedzwa zvakanyanya kana kuchienzaniswa neMIG welding.

二、Kushanda musimboti we mold welding muchina

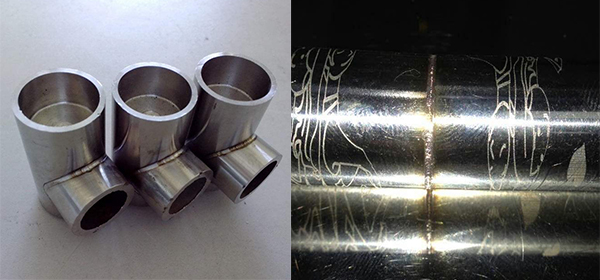

Iyo mold laser welding muchina zvakare ibazi reLaser welding muchina, saka nheyo yekushanda ndeye kushandisa simba guru-laser pulses kuti ridzise zvinhu munzvimbo duku.Simba reiyo laser radiation inopararira mukati mezvinhu kuburikidza nekupisa conduction, uye zvinhu zvacho zvinonyungudutswa nekuumbwa.chaiyo melt pool.Imhando itsva yewelding nzira, kunyanya yewelding yemidziyo yakatetepa-yakakomberedzwa uye yakanyatso mativi, uye inokwanisa kuona nzvimbo welding, butt welding, stitch welding, sealing welding, nezvimwe. musono, hapana chinodiwa kana kurapwa kwakapusa mushure mewelding, yakakwira welding seam mhando, hapana pores, chaiyo kudzora, diki inotarisisa nzvimbo, yakakwirira chinzvimbo kurongeka, uye nyore otomatiki.Yepamusoro-simba laser welding michina yakatangwa, uye akasiyana masitayipi emalaser welding michina uye kugadzirisa zvinogona kuitika kune zvakakora zvinhu.

Muenzaniso:

三、Zvimiro zve mold laser welding

Iyo mold laser welding muchina inotora hombe-screen LCD Chinese interface kuratidza, izvo zvinoita kuti zvive nyore kune anoshanda kudzidza nekushanda.Iyo midziyo zvakare inotora iyo font programming basa kuona akawanda-modhi basa, iro rakakodzera kugadzirisa mold yezvinhu zvakawanda.Kwete chete nzvimbo inopisa-inopisa idiki, chiyero che oxidation chakaderera, asiwo hapazovi nemablister, pores uye zvimwe zviitiko.Mushure mekunge mold yagadziriswa, mhedzisiro yekugadzirisa ndeyekuzadzisa kusaenzana pamubatanidzwa, uye hazvizokonzere kushanduka kwe mold.

四、Kugadzirisa uye kugadzirisa tekinoroji

1.The moldLaser welding muchinainofanira kushandisa 10X kana 15X maikorosikopu kutarisa kushanda.

2. Simba rekushandisa kwe mold laser welding machine inogona kutora waveform inogadziriswa basa, iyo inokodzera welding yezvinhu zvakasiyana.Zvakadai se: simbi inofa, simbi isina tsvina, beryllium mhangura, aluminium, nezvimwe.

3. Iyo CCD system (kamera system) inogona kushandiswa kutarisa, basa nderokuti: kunze kwemushandisi anocherechedza kubva ku microscope, vasiri-operators vanogona kutarisa yose welding process kuburikidza nechiratidziro chechiratidzo chekhamera yekhamera, chigadzirwa ichi chiri inobatsira kune isiri-kushanda Kudzidziswa kwehunyanzvi kwevashandi uye zviratidzo zvekuratidzira kwaita basa rakanaka mukusimudzira tekinoroji yelaser welding.

4. Inogona kunyungudutsa welding waya dzemadhayamita akasiyana, kubva 0.2 kusvika 0.8 mudhayamita.

5. Iyo mold laser welding muchina unofanirwa kuchengetedzwa neargon gasi, uye chirongwa chinofanira kuiswa kuti chibudise argon gasi kutanga uye ipapo laser kudzivirira oxidation yekutanga pulsed laser panguva yekuenderera mberi kwekugadzirisa.

6. Kana mold iri laser welded, chiitiko chinowanzoitika ndechekuti kune mavanga ekuruma akapoteredza chikamu chewelding.Izvo zvinodikanwa kushandisa nzira yelaser air punching kuvhara shanduko dzinogona kukonzera kuruma mamaki kudzivirira kuitika kwekuruma mamaki.Zvakakwana kuti chivara chechiedza chinodarika kumucheto kwenzvimbo yewelding ne 0.1mm.

Nguva yekutumira: Jun-12-2023