Kuwanda kwekushandiswa kweLaser welding michinairi kuramba ichiwedzera, asi zvinodiwa zviri kuramba zvichikwira.Munguva yewelding process, kudzivirira gasi rinoda kupeperetswa kuti ive nechokwadi chekushongedza kwechigadzirwa kwakanaka.Saka sei kushandisa kuvhuvhuta kwemhepo nenzira kwayo mukuita kwesimbi laser welding?

Mune laser welding, kudzivirira gasi kunokanganisa kuumbwa kweweld, weld quality, weld kupinza uye hupamhi, etc. Kazhinji, kuvhuvhuta shielding gasi kuchava nemhedzisiro inobatsira pane weld, asi inogona zvakare kuve nemhedzisiro inokuvadza kana ikashandiswa zvisirizvo.

Positive effect yekudzivirira gasi paLaser welding muchina:

1. Kunyatsofuridza kudzivirirwa gasi kunogona kunyatso chengetedza dziva re weld kuderedza oxidation, kana kutodzivirira kuve oxidized.

2. Inogona kunyatso kuderedza spatter inogadzirwa mukugadzirisa welding, uye kutamba basa rekudzivirira girazi rinotarisa kana girazi rinodzivirira.

3. Inogona kukurudzira yunifomu kupararira kwechidziva che weld painosimbisa, kuitira kuti weld ive yunifomu uye yakanaka.

4. Inogona kunyatso kuderedza weld pores.

Chero bedzi iyo gasi rudzi, gasi kuyerera uye nzira yekuvhuvhuta yakasarudzwa nenzira kwayo, iyo yakanakira mhedzisiro inogona kuwanikwa.Zvisinei, kushandiswa kusina kunaka kwekudzivirira gasi kunogonawo kuva nemigumisiro yakaipa pane welding.

Migumisiro yakaipa yekushandiswa kusina kunaka kwekudzivirira gasi pane laser welding:

1. Insuflation isina kunaka yekudzivirira gasi inogona kukonzera urombo welds.

2. Kusarudza rudzi rusina kunaka rwegasi kunogona kukonzera kutsemuka mukati me weld uye kunogonawo kuguma nekuderedzwa kwema mechanical properties ye weld.

3. Kusarudza gasi risiri iro rinovhuvhuta kuyerera kweyero kunogona kutungamirira kune yakakomba oxidation ye weld (kana iyo yekuyerera yakakura kana yakanyanya kudiki), kana inogona zvakare kukonzera iyo weld pool simbi kuvhiringidzwa zvakanyanya nekunze kwemasimba, zvichikonzera weld kudonha kana kuumba zvisina kuenzana.

4. Kusarudza nzira isina kunaka yekuputira gasi kuchaita kuti weld ikundikane kuita kana kusave nemhedzisiro yekudzivirira kana kuve nemhedzisiro yakaipa pakuumbwa kwe weld.

Mhando yekudzivirira gasi:

Kazhinji kushandiswalaser weldingekudzivirira magasi anonyanya kuve N2, Ar, He, uye maitiro avo emuviri nemakemikari akasiyana, saka mhedzisiro yeweld yakasiyanawo.

Argon

Iyo ionization simba reAr ishoma, uye dhigirii reionization pasi pechiito chelaser rakanyanya kukwirira, izvo zvisingakodzeri kudzora kuumbwa kweplasma makore, uye ichave nemhedzisiro pakushandiswa kunoshanda kwelaser.Nekudaro, basa reAr rakaderera kwazvo, uye zvakaoma kuita kemikari nemasimbi akajairika.kuita, uye mutengo weAr hauna kukwirira.Mukuwedzera, kuwanda kweAr yakakura, iyo inobatsira kunyura kumusoro kwechidziva che weld, iyo inogona kudzivirira zviri nani dziva re weld, saka rinogona kushandiswa seyakajairwa kudzivirira gasi.

Nitrogen N2

Iyo ionization simba reN2 ine mwero, yakakwirira kupfuura iyo yeAri, uye yakaderera pane iyo yaIye.Pasi pechiito chelaser, iyo ionization degree iri pakati, iyo inogona kuderedza zvirinani kuumbwa kweplasma gore, nekudaro ichiwedzera kushandiswa kunoshanda kwelaser.Nitrogen inogona kuita zvemakemikari nealuminium alloy uye kabhoni simbi pane imwe tembiricha kuti ibudise nitrides, izvo zvinowedzera brittleness ye weld uye kuderedza kuoma, izvo zvinova nemhedzisiro yakaipa pamagetsi emagetsi ejoin ye weld, saka ndizvo. hazvikurudzirwi kushandisa nitrogen.Aluminium alloy uye kabhoni simbi welds inodzivirirwa.Iyo nitride inogadzirwa nemakemikari reaction pakati pe nitrogen nesimbi isina tsvina inogona kuvandudza kusimba kweiyo weld joint, izvo zvichabatsira kuvandudza ma mechanical properties of the weld, saka nitrogen inogona kushandiswa segasi rinodzivirira kana welding simbi isina tsvina.

Helium Iye

Ane simba repamusoro reionization, uye dhigirii yeionization yakaderera zvikuru pasi pechiito che laser, iyo inogona kudzora zvakanaka kuumbwa kwegore re plasma.Iyo yakanaka weld yekudzivirira gasi, asi mutengo waIye wakanyanya kukwirira.Kazhinji, gasi iri harishandiswe muzvigadzirwa zvinogadzirwa nevakawanda.Anowanzo shandiswa kutsvagisa yesainzi kana zvigadzirwa zvine kukosha kwakanyanya kwakawedzerwa.

Parizvino pane nzira mbiri dzakajairwa dzekufuridza dzekudzivirira gasi: kuvhuvhuta padivi-shaft uye coaxial kuvhuvhuta.

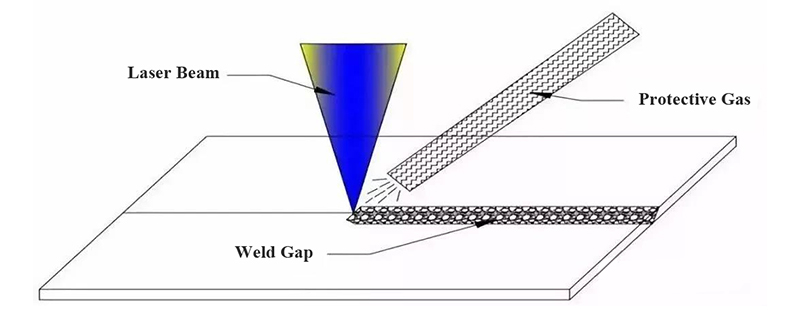

Mufananidzo 1: Side-shaft Kuputika

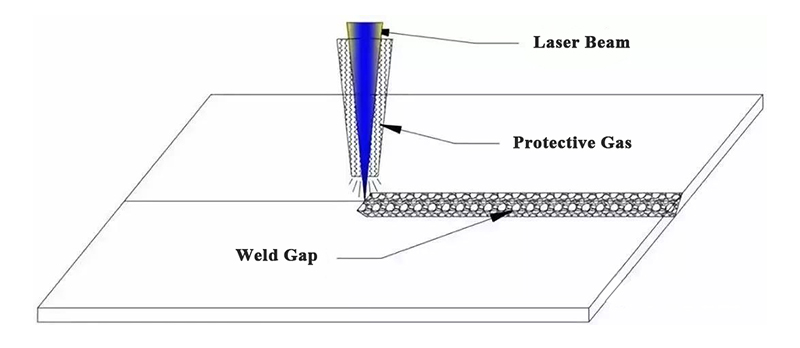

Mufananidzo 2: Coaxial Blowing

Nzira yekusarudza nzira mbiri dzekufuridza ndeyekufunga kwakadzama.Kazhinji, zvinokurudzirwa kushandisa nzira yekuputira inodzivirira gasi nzira.

Iyo sarudzo yekudzivirira gasi kuvhuvhuta nzira: zviri nani kushandisa paraxial kune yakatwasuka mutsara welds, uye coaxial kune ndege yakavharwa magirafu.

Chokutanga pane zvose, zvinoda kujeka kuti iyo inonzi "oxidation" ye weld inongova zita rinowanzozivikanwa.Mukutaura, zvinoreva kuti weld inogadziriswa nemakemikari nezvinokuvadza zvikamu mumhepo, zvichikonzera kuparara kwehutano hweweld.Zvakajairika kuti weld simbi iri pane imwe tembiricha.Inopindirana nekemikari pamwe neokisijeni, nitrogen, haidhirojeni nezvimwe mumhepo.

Kudzivirira kuti weld isave "oxidized" ndiko kuderedza kana kudzivirira zvinhu zvinokuvadza zvakadaro kuti zvisasangana nesimbi inoputika pakupisa kwakanyanya, kwete chete simbi yakanyungudutswa yedhamu, asi kubva panguva yekunyungudutswa kwesimbi ye weld kusvika The pool simbi yaoma. uye tembiricha yaro inodonha pasi peimwe tembiricha mukufamba kwenguva.

Semuenzaniso, titanium alloy welding inogona kukurumidza kutora hydrogen kana tembiricha iri pamusoro pe300 °C, okisijeni inogona kukurumidza kubatwa kana tembiricha iri pamusoro pe450 °C, uye nitrogen inogona kutorwa nekukurumidza kana yadarika 600 °C, saka titanium. alloy weld yakasimbiswa uye tembiricha yakaderedzwa kusvika 300 ° C Zvikamu zvinotevera zvinoda kuchengetedzwa zvinobudirira, zvikasadaro zvichave "oxidized".

Hazvina kuoma kunzwisisa kubva pane tsananguro iri pamusoro apa kuti gasi rinoputika rekudzivirira haringodi kuchengetedza dziva re weld panguva yakakodzera, asi rinodawo kuchengetedza nzvimbo yakangoomeswa iyo yakashongedzerwa, saka kazhinji side shaft side. inoratidzwa muMufananidzo 1 inoshandiswa.Kufuridzira gasi rekudzivirira, nokuti kuchengetedzwa kwenzira iyi yakakura kudarika iyo yecoaxial kudzivirira nzira mumufananidzo 2, kunyanya nzvimbo iyo weld ichangobva kusimba ine kuchengetedzwa kuri nani.

Zvemainjiniya ekushandisa, hazvisi zvese zvigadzirwa zvinogona kushandisa padivi shaft yekufuridza kudzivirira gasi.Kune zvimwe zvigadzirwa, chete coaxial shielding gasi inogona kushandiswa, iyo inoda kuitiswa kubva kune chigadzirwa chimiro uye fomu yakabatana.Sarudzo yakanangwa.

Kusarudzwa kwemaitiro chaiwo ekudzivirira gasi ekuridza nzira:

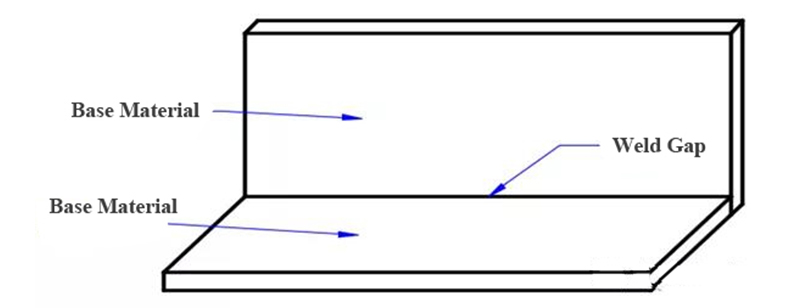

1. Straight Welds

Sezvinoratidzwa muMufananidzo 3, chimiro chewelding seam yechigadzirwa mutsara wakatwasuka, uye fomu rekubatana ijojo rebutt, lap joint, yemukati kona yekona seam joint kana lap welded joint.Zviri nani kuridza gasi rekudzivirira padivi re shaft.

Mufananidzo 3: Straight Welds

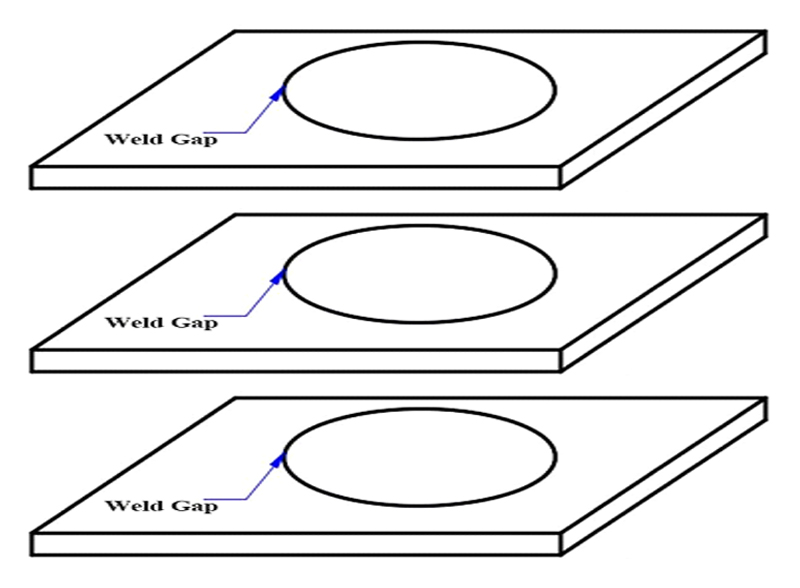

2. Flat yakavharwa graphic welds

Sezvinoratidzwa muMufananidzo 4, chimiro chewelding seam yechigadzirwa chimiro chakavharwa senge denderedzwa rendege, plane polygon, uye ndege ine-multi-segment line.Zviri nani kushandisa iyo coaxial shielding gasi nzira inoratidzwa mumufananidzo 2.

Mufananidzo 4: Flat Yakavharwa Graphic Welds

Kusarudzwa kwekudzivirira gasi kunobata zvakananga kunaka, kushanda uye mari yekugadzira welding.Nekudaro, nekuda kwekusiyana kwezvinhu zvewelding, kusarudzwa kwewelding gasi zvakare kwakaoma mune chaiyo welding process.Izvo zvinodikanwa kunyatso funga nezve welding zvinhu, nzira dzewelding, uye zvinzvimbo zvewelding.Zvakare neiyo inodiwa welding mhedzisiro, chete kuburikidza neyeyedzo yewelding inogona kusarudzwa gasi rewelding kuti riwane zvirinani welding mhedzisiro.

Nguva yekutumira: Chivabvu-08-2023