Laser welding muchinaimhando yemidziyo yewelding inowanzoshandiswa mukugadzirwa kwemaindasitiri, uye zvakare iri muchina unokosha wekugadzirisa zvinhu zvelaser.Laser welding michina yakawedzera zvishoma nezvishoma kubva pakukura kwekutanga kusvika ikozvino, uye mhando dzakawanda dzemichina welding dzakatorwa.

Laser welding imhando nyowani yewelding nzira uye imwe yeakakosha maficha ekushandiswa kwezvinhu zvekugadzira tekinoroji.Laser welding inonyanya kunangwa kune welding yezvakatetepa-madziro zvinhu uye nemazvo zvikamu.Iyo welding process ndeye yemhando yekupisa conduction, kureva kuti, pamusoro peiyo workpiece inopisa nelaser radiation, uye kupisa kwepamusoro kunopfuura nepakati. kudzora ma parameter akadai sehupamhi, simba, peak simba uye kudzokorora frequency ye laser pulse.Iyo inogona kuona nzvimbo welding, butt welding, stitch welding, sealing welding, etc. The welding seam wide idiki, kupisa kwakakanganiswa nzvimbo idiki, deformation idiki, kumhanya kwewelding inokurumidza, musono welding wakatsetseka uye wakanaka, uye hapana kurapwa kana kurapwa kuri nyore kunodiwa mushure mekunama.Iyo welding seam ndeyemhando yepamusoro, haina pores, inogona kunyatso dzorwa, ine diki inotarisisa nzvimbo, uye ine yakakwirira positioning chaiyo, uye iri nyore kuita otomatiki.

Kugadziriswa kwelaser welding muchina:

TheLaser welding muchinainoda kugadziriswa, uye tembiricha yetangi remvura inoda kugadziridzwa munguva yechando nezhizha.Dzivirira tembiricha yemumba kuti isanyanya kutonhora kana kupisa zvakanyanya kukanganisa simba rekubuda kwelaser.Zvinokurudzirwa kugadzirisa tembiricha yetangi remvura kusvika 3 ~ 5 madhigirii yakaderera pane tembiricha yekamuri zvinoenderana nekamuri tembiricha, iyo isingagone kungoita yekuburitsa simba re laser, asi zvakare kuve nechokwadi kugadzikana kwekubuda kwelaser.

1. Kuiswa kwekushisa kwemvura

Iyo tembiricha yemvura inotonhorera ine yakananga kukanganisa kweiyo electro-optical kutendeuka kunyatsoita, kugadzikana uye condensation.Mumamiriro ezvinhu akajairwa, tembiricha yemvura inotonhorera inoiswa sezvizvi: mvura yakachena (inonziwo yakadzika-tembiricha mvura, inoshandiswa kutonhodza laser welding muchina module), tembiricha yemvura yedunhu remvura inofanirwa kuiswa panenge pa21 °C, uye inogona kuiswa zvakakodzera pakati pe20 ne25 °C maererano nemamiriro ezvinhu.Kugadzirisa.Kugadziriswa uku kunoda kuitwa nenyanzvi.

Tembiricha yemvura yemvura yakasvibiswa DI mvura (inozivikanwawo semvura yakanyanya tembiricha, inoshandiswa kutonhodza zvikamu zvemaziso) inofanira kuiswa pakati pe27°C ne33°C.Iyi tembiricha inofanirwa kugadziridzwa zvinoenderana neambient tembiricha uye humidity.Iyo yakakwirira hunyoro, iyo yakakwirira tembiricha yemvura yeDI mvura inofanira kuwedzera zvinoenderana.Nheyo yakakosha ndeye: DI tembiricha yemvura inofanirwa kunge iri pamusoro pedova.

2. Matanho ekudzivirira akadai semukati memagetsi kana optical components

Chinangwa chikuru ndechekudzivirira condensation yemagetsi kana optical components mukati meLaser welding muchina.Ita shuwa kuti chassis haina mhepo: kunyangwe magonhi ekhabhineti aripo uye akavharwa zvakasimba;kana mabhaudhi ekumusoro ekusimudza akasimbiswa;ingave chivharo chekudzivirira chekushandiswa kusingashandiswi kutarisana kwekutonga kuseri kwekasi yakavharwa, uye kana iyo yakashandiswa yakagadziriswa.Chengetedza laser welding muchina uye teerera kune kutevedzana kwekuchinja nekudzima.Isa imba ine air-conditioned yemuchina wekuisa laser welding, shandisa iyo air-conditioning dehumidification basa uye chengetedza iyo air-conditioning ichimhanya ichienderera uye yakatsiga (kusanganisira husiku), kuitira kuti tembiricha uye hunyoro mukamuri ine mhepo ine mhepo zvichengetedzwe. 27°C uye 50% zvichiteerana.

3. Tarisa optical nzira zvikamu

Kuti ive nechokwadi chekuti laser yagara iri mune yakajairika kushanda mamiriro, mushure mekuenderera mberi kwekushanda kana kana yakamira kwenguva yakati rebei, zvinhu zviri munzira yekuona senge YAG tsvimbo, dielectric diaphragm uye lens inodzivirira girazi. inofanira kuongororwa isati yatanga kuve nechokwadi chokuti zvikamu zvemaziso hazvina kusvibiswa., Kana paine kusvibiswa, inofanirwa kubatwa nenguva kuti ive nechokwadi chekuti chikamu chimwe nechimwe che optical hachizokuvadzwa pasi pesimba rakasimba relaser irradiation.

4. Tarisa uye gadzirisa laser resonator

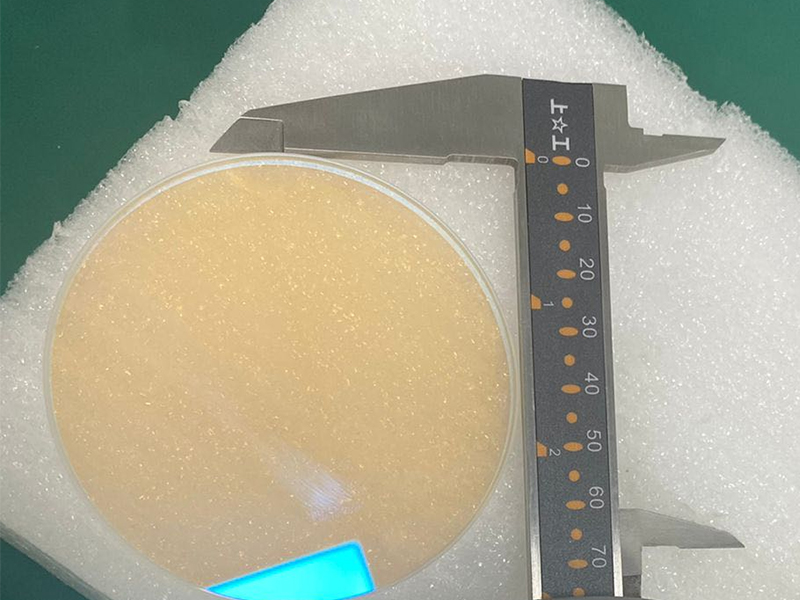

laser welding muchina vanoshanda vanogona kazhinji kushandisa dema mufananidzo bepa kutarisa iyo laser inobuda nzvimbo.Kana iyo isina kuenzana nzvimbo kana kudonha kwesimba kwawanikwa, iyo resonator yelaser inofanirwa kugadziridzwa nenguva kuti ive nechokwadi chemhando yemhando yekubuda kwelaser.Debugging vanoshanda vanofanirwa kuve neruzivo rwakajairwa rwekuchengetedza laser kuchengetedza, uye vanofanirwa kupfeka yakakosha laser kuchengetedza magirazi panguva yebasa.Kugadziriswa kweiyo laser kunofanirwa kuitwa nevashandi vakanyatsodzidziswa, zvikasadaro zvimwe zvinhu zviri munzira yemaziso zvichakuvadzwa nekuda kwekukanganisa kana polarization kugadziriswa kwelaser.

5. Laser welding machine kuchenesa

Basa rega rega uye risati rapera, tanga wachenesa zvakatipoteredza kuita kuti pasi riome uye kuchena.Wobva waita basa rakanaka rekuchenesa iyo YAG laser welding muchina midziyo, kusanganisira yekunze yechasi, iyo yekutarisa sisitimu, uye yebasa, iyo inofanirwa kunge isina tsvina uye yakachena.Malenzi anodzivirira anofanira kuchengetwa akachena.

Laser welding michinaanoshandiswa zvakanyanya mukugadzirisa mazino emazino, jewelry welding, silicon simbi sheet welding, sensor welding, bhatiri cap welding uye mold welding.

Nguva yekutumira: Chivabvu-06-2023