Parizvino,Laser welding michinayakashandiswa zvakanyanya mukushongedza kwekushambadzira, zvishongo, magonhi nemahwindo uye mamwe maindasitiri.Ndeupi musiyano uripo pakati pelaser welding uye argon arc welding, soldering uye mamwe echinyakare welding matekinoroji?Chii chinoitaLaser welding muchinakuvimba kuti zvishoma nezvishoma ive iyo huru yeikozvino welding tekinoroji?

Laser welding muchinaimhando itsva yewelding nzira, kunyanya yewelding yezvakatetepa-walled zvinhu uye yakanaka zvikamu, izvo zvinogona kupedzisa spot welding, butt welding, stitch welding, sealing welding, etc. Small size, diki deformation, fast welding speed, flat uye yakanaka welding seam, hapana chinodiwa kana kurapwa kwakareruka mushure mekucheka, yakakwira welding seam mhando, hapana pores, kutonga kwakaringana, diki mwenje nzvimbo, yakakwirira chinzvimbo kurongeka, nyore kupedzisa otomatiki.Inoshandisa yakakwirira-simba laser pulses kupisa zvishoma zvinhu munzvimbo diki.Simba reiyo laser radiation inopararira mukati mechinhu kuburikidza nekupisa conduction, inonyungudutsa zvinhu kuti zvigadzire dziva rakanyungudutswa, yobva yanyungudutsa zvinhu zviviri izvi zvakasangana pamwechete.

Kuti laser welding inoshanda sei

Laser welding is irradiate high-intensity laser danda kune simbi pamusoro, uye kuburikidza nekudyidzana pakati Laser nesimbi, simbi inonyungudutswa kuita weld.Metal kunyunguduka ndiyo imwe chete yezviitiko zvemuviri panguva yekudyidzana kwelaser nesimbi.Dzimwe nguva simba rechiedza harina kunyanya kushandurwa kuita simbi kunyunguduka, asi rinoratidzwa mune mamwe maitiro, akadai vaporization, plasma kuumbwa, etc. Zvisinei, kuti uwane zvakanaka fusion welding, kunyunguduka kwesimbi kunofanira kuva kunonyanya kushandiswa kwesimba rekushandura.Kuti izvi zviitike, zvinodikanwa kuti unzwisise zvakasiyana-siyana zvemuviri zviitiko zvinogadzirwa mukudyidzana pakati pelaser nesimbi uye hukama pakati peizvi zviitiko zvemuviri uye laser paramita, kuitira kuti yakawanda yelaser simba inogona kudzorwa nekudzora laser paramita.

Inoshandurwa kuita simba rekunyunguduka kwesimbi kuti iwane chinangwa chewelding.

Maitiro paramita ye laser welding

1.Kuwanda kwesimba

Simba density ndeimwe yeanonyanya kukosha ma parameter mu laser processing.Nepamusoro pesimba remagetsi, iyo yepamusoro layer inogona kupiswa kusvika painofashaira muiyo microsecond nguva renji, zvichikonzera kuwanda kwemhepo.Naizvozvo, kusimba kwesimba kwakanyanya kunobatsira pakubvisa zvinhu senge punching, kucheka, uye kunyora.Kudzikira kwesimba remagetsi, zvinotora mamilliseconds akati wandei kuti tembiricha yepasi isvike panovira.Nzvimbo isati yanyungudika, chikamu chepasi chinosvika pakunyunguduka, izvo zviri nyore kugadzira fusion weld yakanaka.Naizvozvo, mu conduction laser welding, iyo simba density iri muhuwandu hwe104 ~ 106W/cm2.

2.Laser pulse waveform

Laser pulse shape inyaya yakakosha mulaser welding, kunyanya kune yakatetepa sheet welding.Kana iyo yakakwira-yakasimba laser beam inorova pamusoro pechinhu, 60 ~ 98% yelaser simba inotaridzwa nekurasika pamusoro pesimbi, uye kutaridzika kunosiyana nekupisa kwepasi.Panguva yekuita kwelaser pulse, iyo reflectivity yesimbi inosiyana zvakanyanya.

3.Laser pulse width

Pulse hupamhi ndiyo imwe yeakakosha paramita ye pulse laser welding.Haisi chete yakakosha parameter yakasiyana nekubvisa zvinhu uye kunyunguduka kwezvinhu, asiwo yakakosha parameter inosarudza mutengo uye huwandu hwemidziyo yekugadzirisa.

4. Kufurira kwehuwandu hwe defocus pane welding quality

Laser welding inowanzoda imwe nzira yekubvisa, nekuti simba repakati penzvimbo panzvimbo yelaser tarisiro yakakwira zvakanyanya, uye zviri nyore kubuda mugomba.Iyo simba density kugovera kwakafanana kune dzimwe ndege dziri kure neanotarisa laser.

Pane nzira mbiri dzekubvisa pfungwa: yakanaka defocusing uye negative defocusing.Iyo yakatarisana nendege pamusoro peiyo workpiece yakanaka defocus, zvikasadaro iyo yakaipa defocus.Zvinoenderana neiyo geometrical optics theory, kana defocus iri yakanaka, kuwanda kwesimba pane inoenderana ndege inenge yakangofanana, asi chimiro chedziva rakanyungudutswa rakawanikwa rakatosiyana.Kana iyo defocus isina kunaka, kudzika kwakakura kwekupinda kunogona kuwanikwa, kunoenderana nekuumbwa kwechidziva chakanyungudutswa.Miedzo inoratidza kuti kana laser yadziirwa kwe50 ~ 200us, zvinhu zvinotanga kunyunguduka, zvichigadzira simbi yemvura uye kupfumbuka, ichigadzira musika-kudzvanywa chiutsi, chinoburitswa nekumhanya kwakanyanya, kuchiburitsa mwenje chena unopenya.Panguva imwe cheteyo, kuwanda kwemhute kunofambisa simbi yemvura kumucheto kwedziva rakanyungudutswa, richigadzira kuora mwoyo pakati pedziva rakanyungudutswa.Kana iyo defocus isina kunaka, iyo mukati mesimba density yezvinhu yakakwira kupfuura iyo yepamusoro, uye zviri nyore kuumba kwakasimba kunyunguduka uye vaporization, kuitira kuti simba rechiedza rifambiswe zvakadzika mukati mechinhu.Nokudaro, mukushandiswa kunoshanda, apo kudzika kwekupinda kunodiwa kuti kuve kwakakura, kukanganisa kusina kunaka kunoshandiswa;kana welding zvinhu zvitete, zvakanaka defocusing inofanira kushandiswa.

Kuenzaniswa neyechinyakare welding tekinoroji,Laser welding muchinaine zvinotevera zvakanakira

1. Iine mabasa akasiyana-siyana akazara, uye welding seam idiki, iyo inogona kuona chaiyo welding;

2. Chimiro chekugadzira chinoshandiswa-chinoshamwaridzana, musoro we laser unogona kutambanudzwa shure uye mberi, kuruboshwe uye kurudyi, kumusoro uye pasi pasi nemaoko, yakakodzera kusabatana uye kureba-welding yezvigadzirwa zvakasiyana-siyana;

3. The welding seam yakatsetseka, iyo welding chimiro yunifomu, hapana pores, hapana kusvibiswa, uye mashoma kubatanidza kukanganisa;

4. The welding speed is fast, the aspect ratio ihombe, deformation idiki, uye kuita kwakagadzikana, kunogona kuona otomatiki misa kugadzirwa;

4.Iyo rudzi rutsva rwekugadzirisa nzira.Laser welding inonyanya kunangwa kune welding yezvakatetepa-madziro zvinhu uye nemazvo zvikamu.Inogona kuona nzvimbo welding, butt welding, stitch welding, sealing welding, etc. Nzvimbo diki yakakanganisika, diki deformation, kukurumidza welding kumhanya, yakatsetseka uye yakanaka welding seam, hapana chinodiwa kana kurapwa kwakapusa mushure mekugadzira, yakakwira welding seam mhando, isina pores, kunyatso kudzora, diki yekutarisisa nzvimbo, yakakwirira chinzvimbo, nyore kuwana otomatiki, saka inofarirwa nevashandisi, kwete chete inovandudza mashandiro ekugadzira uye kugadzirisa, asi zvakare inoderedza rinozotevera rinorema post-kugadzirisa basa.

Laser welding industry

Automotive indasitiri, chakuvhe indasitiri, zvokurapa indasitiri, jewelry indasitiri, etc. Different maindasitiri zvinoda akasiyana Laser welding michina.

Type yeLaser welding muchina

1.Fiber laser welding machine-Handheld Type

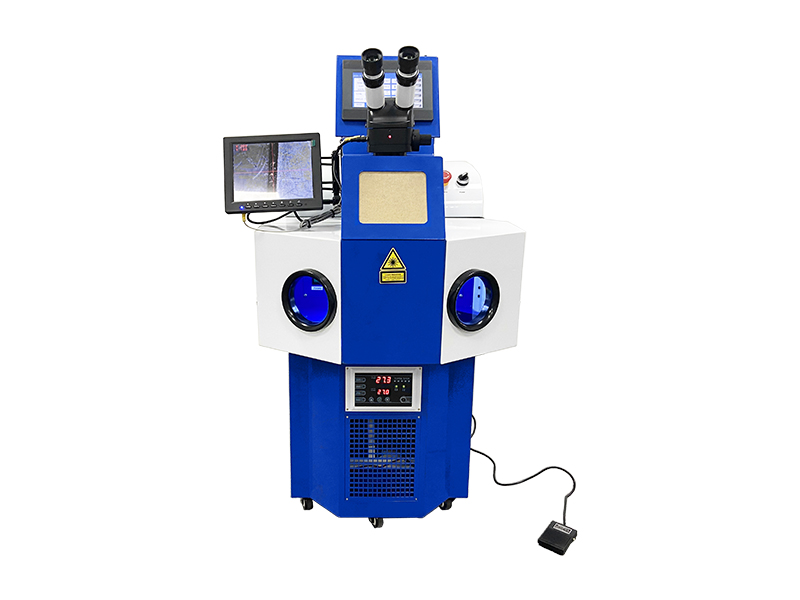

2.Mold laser welding machine- Manual Type

3.Cantilever laser welding machine-Neruoko rune usimbe

4.3-Axis laser welding muchina-Otomatiki Type

5.Jewelry laser welding machine-Desktop Type

6.Jewelry Laser welding machine-Inbuilt Water Chiller

7.Jewelry laser welding machine-Separate Water Chiller

Mienzaniso:

Nguva yekutumira: Kubvumbi-27-2023