Mumakore achangopfuura, kuvandudzwa kweindasitiri yekugadzira kwave kwakakurumidza, uye kudiwa kwesimbi kugadzirisa kwakawedzerawo.Welding ndeimwe yemaitiro akakosha ekugadzirisa simbi, uye tsika dzechinyakare dzekugadzira dzakatadza kuzadzisa zvinodiwa zvekugadzira.Muchiitiko ichi, iyoruoko-akabata laser welding muchinaakaberekwa, iyo yairumbidzwa nevakawanda payakatangwa, uye nekukurumidza yakatsiva yechinyakare welding yakaonda ndiro yewelding musika.

Theruoko-akabata faibha laser welding muchinachizvarwa chitsva che laser welding michina.Ndezvekusabatika welding.Hazvidi kumanikidzwa panguva yekushanda., iyo inonyungudutsa zvinhu mukati, uye zvino inotonhorera uye crystallizes kuita weld.

a.Hapana simba rekunze richashandiswa pane workpiece

Kana iyo inobatwa nemaoko laser welding muchina inogadzira zvikamu, sezvo isingazosangana nezvikamu zvakagadziriswa, hapazove nekushushikana kwekunze pane zvakagadziriswa zvikamu panguva yese yekushongedza, uye simba rekuisa rinogadzirwa nelaser rakanyanyisa. high.Iko kupisa kwemafuta pane zvakatenderedza chikamu idiki, saka chikamu hachizoremara panguva yewelding.

b.Welding pakati pezvinhu zvakasiyana zvinogona kuitika

Mune yechinyakare welding process, kazhinji chete maviri maworkpiece akagadzirwa echinhu chimwe chete anogona kugadzirwa, asi iyo laser welding process yemuchina wepamusoro-wakabatwa nelaser welding muchina haungogone kunyunguduka yakakwirira uye zvinhu zvakasiyana-siyana zvakaoma kunyunguduka uye weld. , Zvakadai setitanium alloy, aluminium alloy nezvimwe zvinhu.Uye zvakare, iyo laser welding process tekinoroji inogona zvakare kuona welding pakati pezvimwe zvinhu zvakasiyana, ichityora muganho welding pakati pezvinhu.

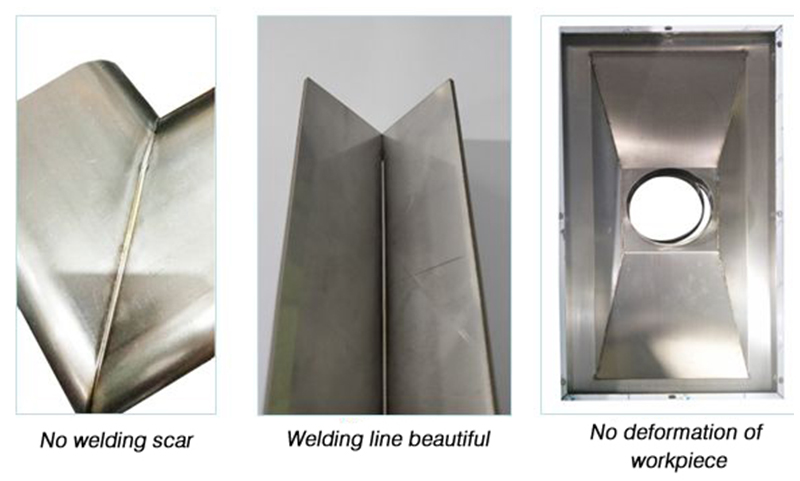

c.Narrow welding seam, yakatsvinda uye yakanaka kutaridzika

Iyo laser welding tekinoroji yemuchina wakabatwa nemaoko laser welding yakakwira zvakanyanya, haingosvibise nharaunda chete, asi zvakare inoumba majoini madiki ekutengesa, akamanikana welding seams, yunifomu yekushongedza seam chimiro, mashoma mapores uye hurema, hunogona kuderedza uye hurema. optimize kusvibiswa kwezvinhu zvevabereki, Naizvozvo, mushure mekucheka, kwete chete kupikisa kwakasiyana-siyana kwakanaka, asi pamusoro pechinhu chacho zvakare chakanyatsonaka uye chakanaka.

Zvimiro zveruoko-akabata laser welding muchina:

1. Chigadzirwa chacho chiduku muhukuru

2. Flexible uye nyore kushanda, anogona kuziva panze welding

3. Yakanaka danda remhando, kukurumidza kukurumidza, diki deformation yekupisa, kurongeka uye kubatanidzwa kwepamusoro

4. Iyo welding seam yakanaka, yakapfava uye isina pores, uye hapana kurapwa kana kurapwa kuri nyore kunodiwa mushure mekushongedza.

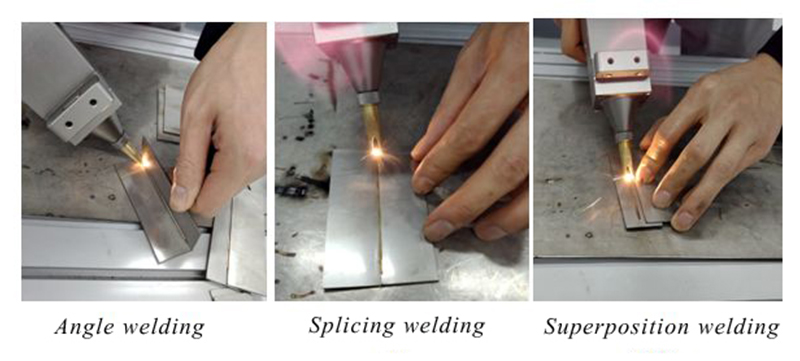

5. The hand-held welding pfuti inogona weld workpiece pane chero kona, iyo inokodzera nzvimbo welding ye welds yakaoma uye michina yakasiyana-siyana.

Zvakanakira zvemaoko-akabata laser welding muchina:

1. Kushanda kuri nyore uye kuri nyore kushandisa: ruoko rwakabata laser welding machine iri nyore kushanda uye ine mari shoma yebasa.

2. Fast welding speed: Muchina unobatwa nemaoko laser welding unoenderera mberi, simba resimbi rakanyanya, welding inoshanda uye inomhanya-mhanya, nzvimbo yewelding idiki, nzvimbo inobatwa nekupisa idiki, musono we welding wakatsetseka. uye yakanaka, uye kugaya kunotevera kunoderedzwa.

3. Zvishandiso zvakasiyana-siyana zvewelding: Muchina unobatwa nemaoko welaser welding unogona kubatanidza zvinhu zvakajairika zvesimbi zvakadai semahwendefa esimbi isina tsvina, mahwendefa esimbi, marata, uye mahwendefa ealuminium.

4. Yakaderera kugadzirisa nharaunda zvinodiwa: Iyo inobatwa nemaoko laser welding muchina haidi yakakosha welding tafura, iyo midziyo inotora nzvimbo diki, uye kugadzirisa kunoshanduka.Iyo inoshongedzerwa nemamita akati wandei e optical fiber yekuwedzera mitsara, iyo inogona kutamiswa kuti iite kureba kushanda pasina zvirambidzo zvenzvimbo.

5. Basa rakagadzikana: Laser yakashongedzerwa nemidziyo yekutonhodza mvura, iyo inogona kuve nechokwadi chekuenderera kwepamusoro-simba basa.

6. Kushanda kwemari yepamusoro: Muchina wakabatwa nemaoko laser welding haugoni kungoita mabasa ekugadzirisa, asiwo kugadzirisa molds.Hupenyu hwelaser i100,000 maawa, ayo akareba kupfuura hupenyu hwesevhisi yemidziyo yakajairwa, uye inodhura-inoshanda.

Kuenzanisa kwekushandiswa kwesimba pakatiruoko-akabata laser welding muchinauye argon arc welding:

Kuenzaniswa neyechinyakare arc welding, iyo inobatwa nemaoko laser welding muchina inochengetedza ingangoita 80% kusvika 90% yemagetsi emagetsi, uye mutengo wekugadzirisa unogona kudzikiswa ne30%.Welding mhedzisiro kuenzanisa: ruoko-yakabata laser welding muchina unogona kupedzisa dissimilar simbi uye dissimilar simbi welding.Kukurumidza kumhanya, kudiki deformation uye kudiki kupisa kwakakanganiswa nzvimbo.Mawelds akanaka, akapfava, uye haana/ashoma porosity.Ruoko rwakabata laser welder yezvikamu zvidiki zvakavhurika uye welding.Kutevera maitiro ekuenzanisa: Iyo ruoko-yakabata laser welding muchina ine yakaderera kupisa kupinza uye diki deformation yeworkpiece panguva yewelding, uye inogona kuwana yakanaka welding pamusoro pasina kana chete kurapwa kwakapusa (zvichienderana newelding surface effect zvinodiwa).Iyo inobatwa nemaoko laser welding muchina unogona kudzikisa zvakanyanya mutengo webasa weiyo hombe yekupukuta uye yekumisa maitiro.

Mashandisirwo eminda yakabatwa nemaoko laser welding muchina:

Kunyanya kune yakagadziriswa chinzvimbo chesimbi yakakura uye yepakati-kati, kabati, chassis, aluminium alloy gonhi uye hwindo furemu, simbi isina tsvina yekugezera bheseni uye zvimwe zvakakura workpieces senge yemukati yekurudyi kona, yekunze kona yekurudyi, ndege weld welding, kupisa kudiki kunokanganisa. nzvimbo panguva yewelding, diki deformation, uye welding kudzika Yakakura uye yakasimba welded.Inoshandiswa zvakanyanya mukicheni neindasitiri yekugezera, indasitiri yemidziyo yemumba, indasitiri yekushambadzira, indasitiri yeforoma, indasitiri yesimbi isina tsvina, indasitiri yeinjiniya yesimbi, indasitiri yemasuo nemahwindo, indasitiri yemaoko, indasitiri yezvigadzirwa zvemumba, indasitiri yefenicha, indasitiri yezvikamu zvemotokari, nezvimwe.

Iko kushandiswa uye kungwara kweLaser welding michinavave midziyo ine simba mumichina yemaindasitiri.Iyo yepamusoro yekugadzirisa kuita uye yakanakisa kugadzirisa maitiro emaoko-akabatwa laser welding michina yakagadzira yakakwira mipiro mukugadzirwa kwemabhizinesi makuru., ndiyowo sarudzo yezvizhinji zvekugadzira zvidyarwa.

Nguva yekutumira: May-10-2023